The UGM Quality Management Process

Being consumers ourselves, we believe supreme quality and safety of dietary supplements is of upmost importance in the manufacturing process. All our products and manufacturing processes go through the UGM Quality Management Process to ensure strict quality management is applied.

Our in-house Quality Control team ensure that only ingredients and materials of the best quality are used in our development and manufacturing process. UGM also has our own Quality Assurance team, who scientifically analyze every step of our process to prevent potential risk factors in advance.

1. Establishing Manufacturing Procedures

With every project, we start with establishing the requirements in accordance to our end goal. At this stage, our team will analyse risk factors, strategies, and resources associated with processes involved in the manufacturing process.

2. Implementation

Following the finalization of the project blueprint, our team will evaluate and prepare our facility for production. Each process will be carefully documented, and calibrated for optimal use of time and resources.

3. Monitoring

As the manufacturing process begins, our dedicated Quality Assurance team will monitor and conduct internal audits for our processes to ensure safety and quality of products and equipment are of viable standards. Our team also handles deviation and change management

4. Inspection and Verification

Every batch of products and packaging manufactured go through strict inspection and verification processes by our quality committee. Product quality is tested and evaluated to ensure only the best are presented to our clients.

5. Problem-solving and Improvement

All UGM’s manufacturing processes and procedures are subject to review to identify potential issues to prevent recurrences in future implementation. Our QA and QC teams work together closely in improving and streamlining possible processes for increased efficiency.

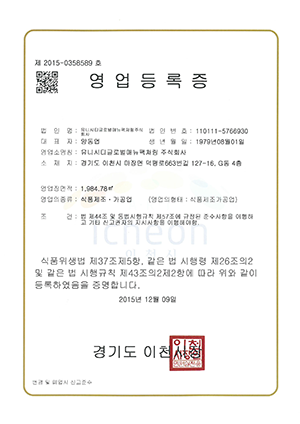

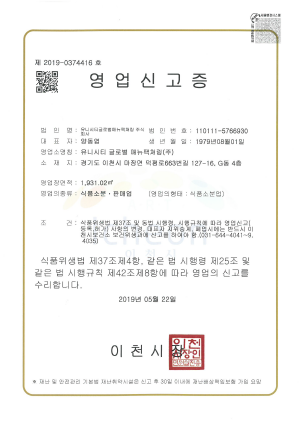

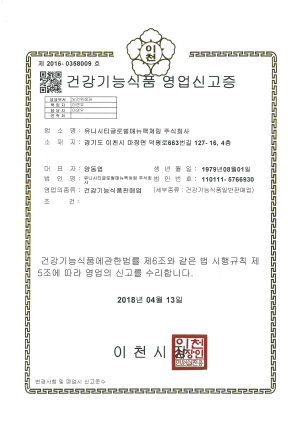

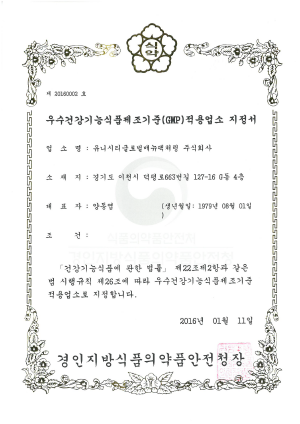

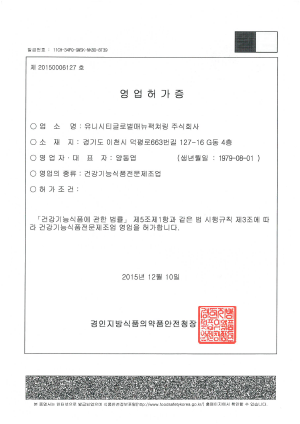

South Korea

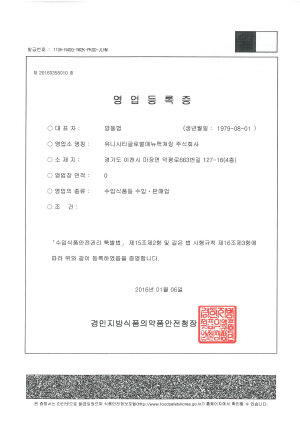

South Korea